Email: [email protected]

-

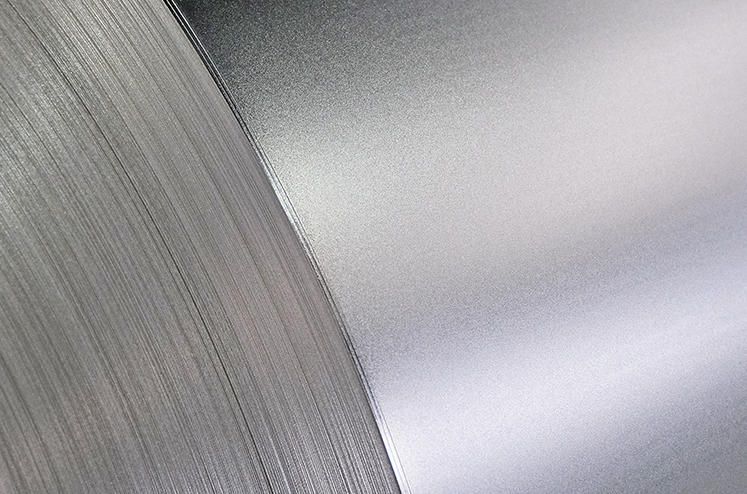

Excellent and stable product quality.

Strict production process design and program control make each batch of products more stable and traceable, achieving high consistency and stability of products.

-

High cost performance and gold content of products.

The company's superior geographical location and capable management team reduce transportation and labor costs; the professional R&D team and technical service team can continue to provide cost-effective new products.

-

Continuous and reliable product supply.

The company has sufficient production capacity and has a high degree of control over the price, quality and stable supply of raw materials, laying the foundation for sustainable production.