Email: [email protected]

Tinplate Coil Cut

After the steel enters the factory, the steel plate is leveled by a leveler, and then the steel plate is cut into appropriate specifications by a shearing machine or a cutting machine.

Tinplate Coil Coat

In order to produce a certain gloss on the printed surface, white varnish can be applied as the base color before printing on the metal printing press.

Tinplate Coil Printing

The surface of the semi-finished product after drying is printed with a printing machine, and the printing material is made of environmentally friendly UV ink.

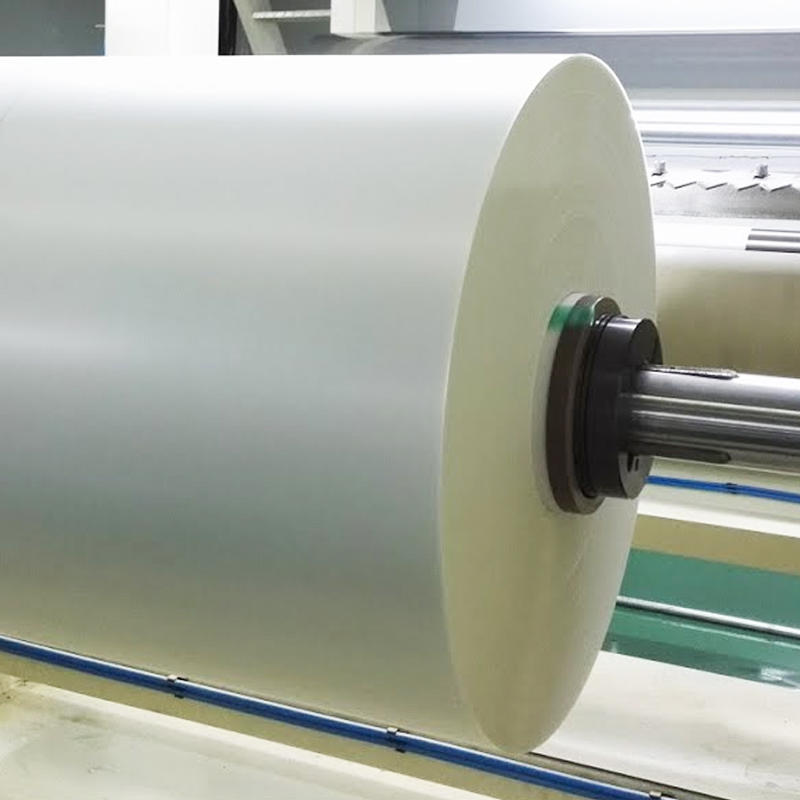

Pet Coating For Tinplate Packaging

PET coating for tinplate packaging is a composite material that combines plastic film on cold rolled thin steel plate by melting method, and is a steel deep processing product.

Suzhou Jinqiao Packaging Container Co., Ltd. was founded in 2004. It has been specialized in mass production of tinplate containers such as chemical cans and food cans for 19 years. At the same time, it has a complete industrial chain from raw material tinplate, unpacking, printing to production of tin cans.

Jinqiao has a large number of modern production equipment, with an annual production capacity of 50 million pieces.The company has obtained the designated certificate of hazardous chemical packaging container issued by the state and the certificate of national high-tech enterprise.

We have a strong R&D team,and we can develop and produce products according to the drawings or samples the customers offered.

We have two own factories, so we can provide competitive favorable price and high quality products directly.

Our freight teams and shipping partners find end-to-end fulfillment solutions to deliver your packaging immediately or via a scheduled recurring delivery program.

Pet food tin boxes are generally safe for storing pet food, provided they are made from appropriate materials and constructed with food safety in mind...

Pet food tin boxes are constructed from a variety of materials designed to ensure safety, durability, and functionality. Here are the common materials...

Tinplate steel coil is a versatile material with a wide range of applications due to its combination of the corrosion resistance of tin with the stren...

The base metal used for tinplate steel coil is typically low carbon steel, which is chosen for its ductility, formability, and weldability. This base ...

Cold-rolled steel coils are versatile materials used in a wide range of applications across various industries due to their excellent formability, sur...